In response to the rapidly changing market needs, we believe it is our mission to plan and propose new materials based on fermentation. In order to work in a consistent structure, from the planning of new raw materials to the development of new products and manufacturing, we mainly use fermentation technology as we carry out our daily research and development

Our company was selected under the “Subsidies to support the development of new manufacturing, commerce and services“ in 2013, 2014 and 2015, and under the “new Aichi creative research and development subsidies“ in 2017, 2018, 2020, 2022, 2023, and 2024.

-

Developing and manufacturing unique and natural functional materials

Since our founding in 1984, we have been developing functional materials by using unique fermentation technology in the food and cosmetic fields. The development is creative and uses techniques to bring out the hidden abilities of microorganisms. The keywords in development are “highly functional“ and “high added value.“ Added value has been created by transforming natural materials by using the power of microorganisms to increase their existing functionality or to create a new functionality. The materials created by gathering all of these technologies have a high level of functionality and safety and are well recognized not only within Japan but also overseas.。

-

-

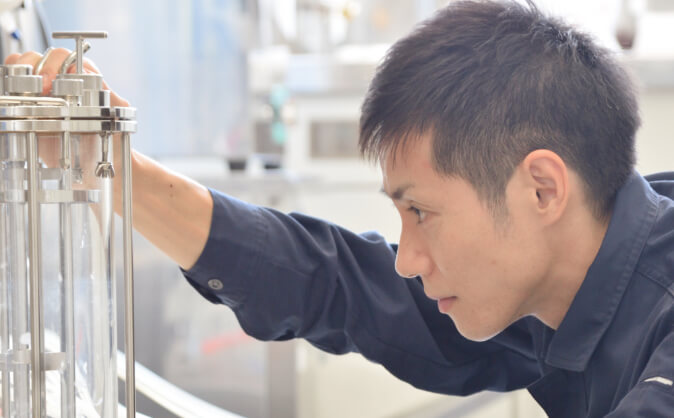

A group of engineers with overwhelming creativity

TOYO HAKKO has many engineers with knowledge in a variety of fields, including Doctors of Science who are good at basic research and nationally certified nutritionists who are particularly skilled at developing formulas for fermented materials. The products created by combining their knowledge are truly one of a kind, and their creativity for maximizing the abilities of microorganisms is unrivaled.

-

Attitude towards quality assurance

Ensuring the quality of the products is the manufacturer’s responsibility and is also an essential element. Given this, TOYO HAKKO conducts a thorough quality management, from the acceptance of the raw materials to shipping the products. This also includes analyzing the ingredients, such as performing microorganism tests and physiochemical tests of the raw materials used, as well as conducting factory inspections and giving improvement instructions to the raw material manufacturers and processing manufacturers. In addition, for the products in the development stage, toxicity tests are conducted by an external testing laboratory to assure safety based on scientific grounds.

Cooperative research with academic institutions

TOYO HAKKO has conducted cooperative research with a large number of universities, including Nagoya University, Gifu University, Meijo University, Sugiyama Jogakuen University, and Ritsumeikan University. We have transformed the seeds possessed by the universities into functional materials, and in multiple cases, patent applications were filed based on functionality assessments during in vivo testing using TOYO HAKKO’s materials.

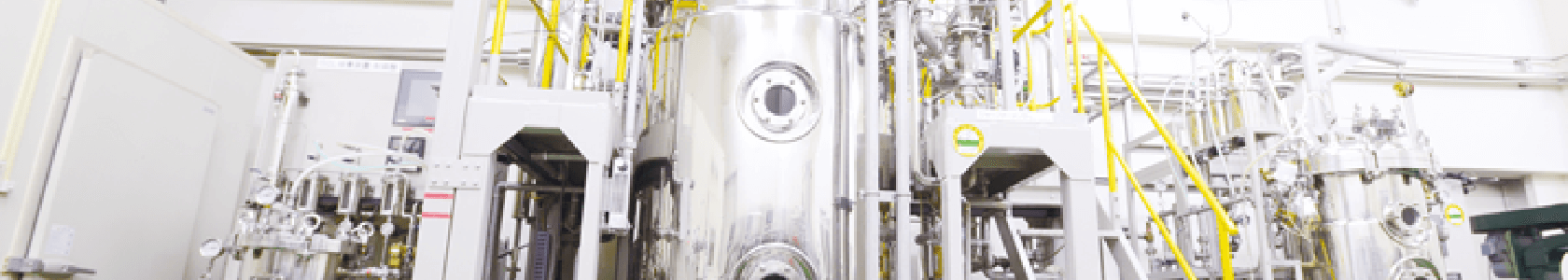

Possess many high performance equipment

We have a large number of high performance facilities and equipment, including laboratory instruments used for basic research, analysis devices required for functionality assessments and quality assurance, and actual production machines to manufacture fermented materials. With this equipment, we are able to transform highly functional, high quality fermented materials into products.

Head office and laboratory

Head office and laboratory